At present, PRODESA is participating in several revamping Projects around the globe. Most of them are in the field of biomass, where the investment greater and the expertise is indispensable. USA, Canada, Russia, Latvia, Vietnam and Spain are only some examples of countries where this kind of projects are placed.

This revamping has been a type of project aimed at disassembly a Regenerative Thermal Oxidizer (RTO) installed by PRODESA in 2011 for a relevant pharmaceutical company to assembly it in its parent company in Rodano (Italy). This contract has a special significance for PRODESA because our client has ordered us the maintenance of its RTO since the equipment was commissioned for the first time and now has placed its trust in us for these tasks that allows us to work for another company of its group.

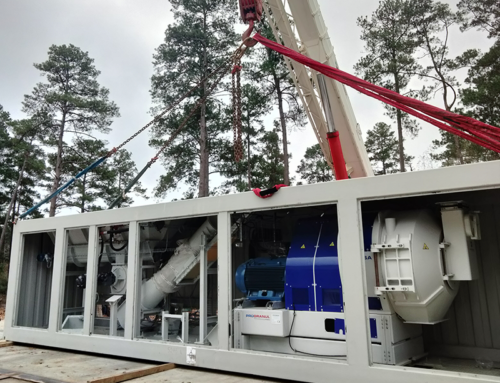

Image of the actual ubication of the RTO in Spain

PRODESA has the expertise and know how needed to carry out revamping projects, and in this project the following phases are going to be carried out:

- SITE SURVEYS: Prodesa has extracted the data and measurements available in the existing plant required to elaborate the disassembly and assembly procedure manual. Currently, PRODESA is preparing all documentation required by the engineering team of its clients involved in the permitting procedure for carrying out the activities. Communications between technical departments have to be fluent and clear. In this way some meetings and conference calls have been set up.

- ASSESSING THE AVAILABLE DOCUMENTATION: In this case, the work has been easier than other projects due to the existing plant was designed, manufactured and installed by Prodesa. Some modifications executed by the client during last years have been checked and recorded.

- EVALUATING THE PRESENT STATUS OF THE EQUIPMENT: PRODESA has been responsible for maintaining the plant from the beginning, so this task also has been easier than usual. The plant has been working properly all these years but the equipment was shut off few months ago, so a general revision is required.

- DEFINING DIASSEMBLY AND ASSEMBLY MANUALS: PRODESA designs the procedures required for the disassembly, uploads, transport, downloads, and assembly tasks.

- SCHEDULING THE PROJECT: It is important to do the activities in an adequate period of time. In this case, one of the companies has to send all the data about its emissions to the local government, so we are going to use its technical shut down of the factory for maintenance to carry out the changes of the programming and wiring (during August). On the other hand, the other company requires the RTO by the end of the year, so the rest of the tasks will be carried out from October on. All the purchase orders to providers has been Scheduled taking these issues in account.

- SUPERVISING THE DISASSEMBLY & THE INSTALLATION IN THE NEW LOCATION. PRODESA will be present during the execution of this revamping in order to control all the activities and avoid problems with the rest of the elements of each factory.

- COORDINATING AND SUPERVISING THE COMMISSIONING AND COLD START-UP: PRODESA will program the PLCs of the plants and will carry out the commissioning of the upgraded installation after assembly.

- SITE ACCEPTANCE TESTING OF THE INTEGRATED SYSTEM: This step will not be different from a normal project. After the commissioning, PRODESA ensures that the system is working without problems.

Leave A Comment