Once PRODESA obtains the trust of a client to carry out a project and it goes through the engineering, design and manufacturing phase, a key phase for the success of the contract is The Logistics Stage.

We present the highlights of a successful Purchasing and Logistics Department job, through the Eastwood project’s Phase I, taking place in Vietnam.

- 25,556 Nautical Miles.

- 9,703 Road kilometers.

- 480 cubic meters.

- 195 packages.

- 85 metric tons.

- 14 containers.

- 7 Points of Loading.

- 4 Countries of origin.

- 3 Vessels

- 2 days between first and last FOB.

- 1 Harbor personnel strike.

- 1 Massive cyber attack to one Shipping Company.

- 1 Final destination. Saigon (Vietnam)

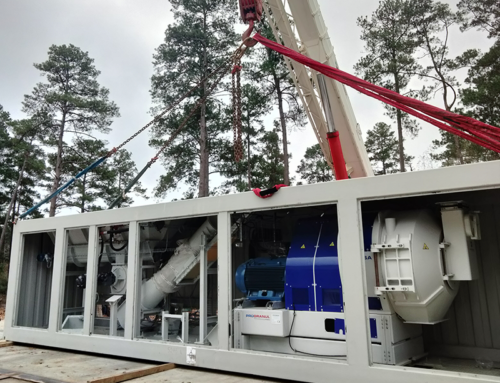

The project consists on the provision of a belt drying and its feed system by moving floor.

Our equipment will be installed in an existing pellet plant in Vietnam.

The size of this Belt Dryer is 130 m2 and will produce 10 ton / h dry microchips and sawdust.

Why do we call this logistics project small but demanding? It may seem that 14 containers is a relatively low figure, especially if compared to previous PRODESA projects: 75 sent for Green Pellet Sarawak (Borneo), 175 for Asia Les (Russia), 120 for Colombo Energy (USA) or the latest Avoti (in Latvia), for which are estimated to be approx. 110. However, we consider it to be highly demanding due to the tight deadline combined with the dispersion of loading points.

And now, thanks PRODESA’s logistic team assembly stage has already started in Eastwood and everything is in order!

Leave A Comment